On the outside, vertical carousels look a lot like a vertical lift module – and the basic result is the same for each of these vertical storage units: Convenient, quick and efficient delivery of pick materials to an ergonomically designed pick station. Both of these automated storage retrieval systems increase efficiency, reduce errors and significantly bump up productivity.

On the outside, vertical carousels look a lot like a vertical lift module – and the basic result is the same for each of these vertical storage units: Convenient, quick and efficient delivery of pick materials to an ergonomically designed pick station. Both of these automated storage retrieval systems increase efficiency, reduce errors and significantly bump up productivity.

The difference is that in a vertical carousel, the trays move in a large oval rotation to bring the products or materials to the operator. In a vertical lift module, an extractor moves inside the machine and pulls the correct tray to deliver to the operator. Both work extremely well with inventory-management software. (To read more about which might work better for you, click here.)

Like other automated storage retrieval systems, vertical storage carousels use hardware and software to create a highly efficient warehouse environment that comes with a pallet full of benefits. These carriers can support many facets of product, part or order processing – including order picking, storage, kitting, consolidation, assembly, production, replenishment and security.

A vertical carousel has advantages in the areas of productivity, space utilization, safety, ergonomics and more – and Outsource Equipment offers both new and pre-owned automated vertical storage systems. Contact us today for more information on our vertical carousel storage systems.

Increase Productivity 2.5 Times over Static Solutions

Increase Productivity 2.5 Times over Static Solutions

- Materials are delivered directly to the operator, minimizing walking, climbing, bending and reaching for heavy objects.

- Pass-through design eliminates time-consuming transport of items from floor to floor.

- Out-of-balance capability provides trouble-free picking with no need to redistribute carrier loads.

- Point-of-use set-up keeps parts closer to the operation, eliminating trips to cribs or stock rooms.

- Shortest-path retrieval system speeds efficient picking

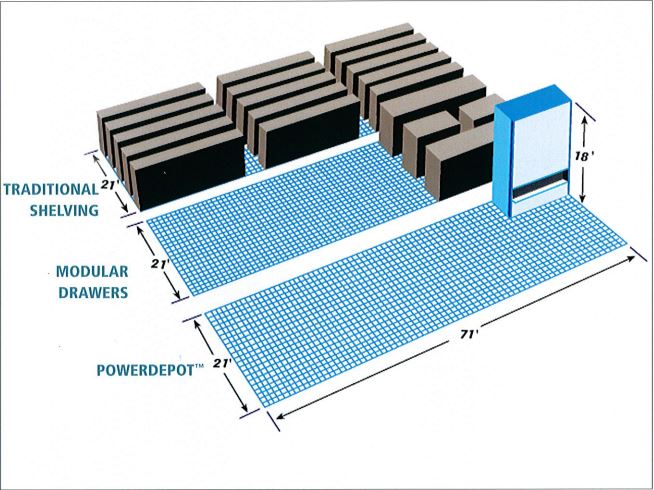

Maximize Space Utilization

- All available vertical height is utilized, reducing floor-space requirements.

- Underused racks, shelves and drawer units are eliminated.

- Aisles are cleared of clutter.

Enhance Safety & Ergonomics

- No more risk of injury climbing up and down ladders to retrieve heavy or bulky items.

- All materials are delivered to operators at an ergonomically correct waist-high position, reducing the potential for back injuries. (For more on ergonomics and the golden zone, click here.)

- A work counter enables picking while the product is out of the carrier or can be used as a place to rest product that is waiting to be loaded.

- Parts are protected from particulates while inside the carousel’s fully enclosed system.

Vastly Improve Control

- Pick product by carrier or part number.

- Host-interface capability for advanced inventory management and control.

- Manual carrier jog buttons to override automated machine control.

- Organized storage of raw material and finished product is possible within the same unit.

- Lockable doors provide additional security.

The POWERdepot from Modula

The POWERdepot, Modula’s leading-edge vertical carousel storage and automated storage retrieval system, is engineered with innovative features that put it far ahead of conventional vertical carousels:

Vertical Carousel POWERdepot

- Dual-chain guidance technology with an 8-fold suspension arm system for optimized load bearing

- Dual-motor drive enables greater width capabilities and provides redundancy for continuous up-time.

- Stainless steel work counter and locking bi-parting doors

- Product protection through enclosed dust cover panels

- Maximized cube and carrier capability of up to 2,200 lbs

- Limitless carrier configurations up to 19-feet wide

- Customizable to application-specific set-ups; available options include 100% extendable pull-out drawers, shelves, dividers, inserts, automatic-door systems, clean-room and cold-room units, and dual access (front and rear or multiple floors)

- State-of-the-art safety features like personnel and product protection, light curtains, e-stops and motor-overload sensors

- Customizable, easy-to-use operator interface that provides control and security

- Lower maintenance costs

- Software to further enhance the process