Are You Out of Space?

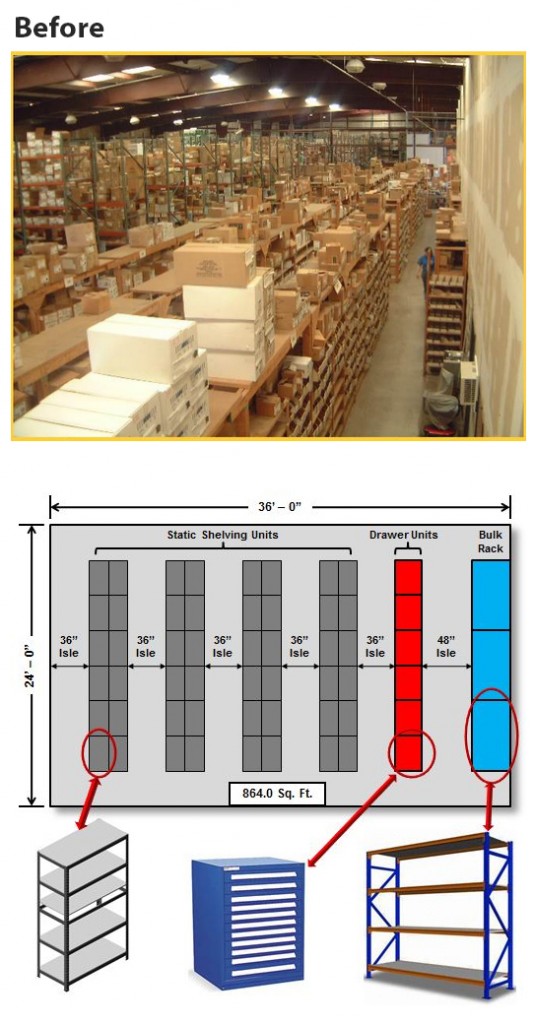

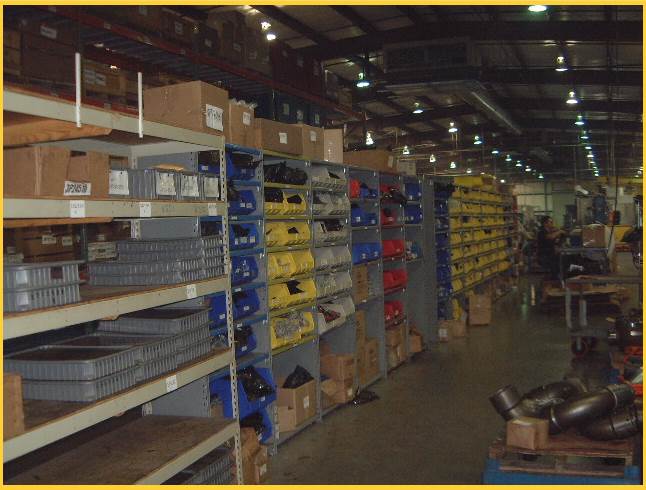

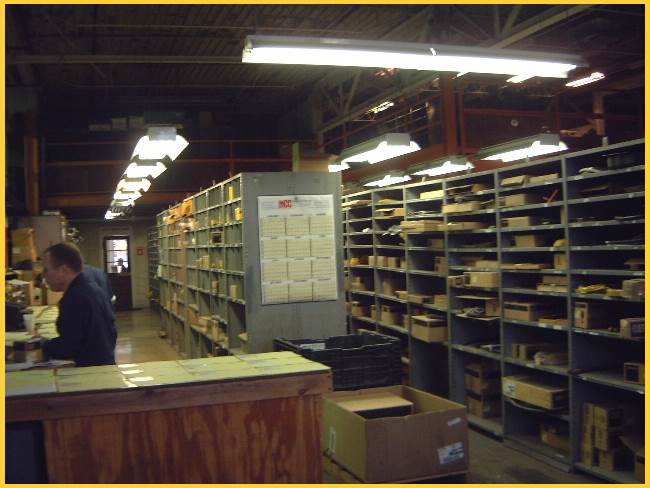

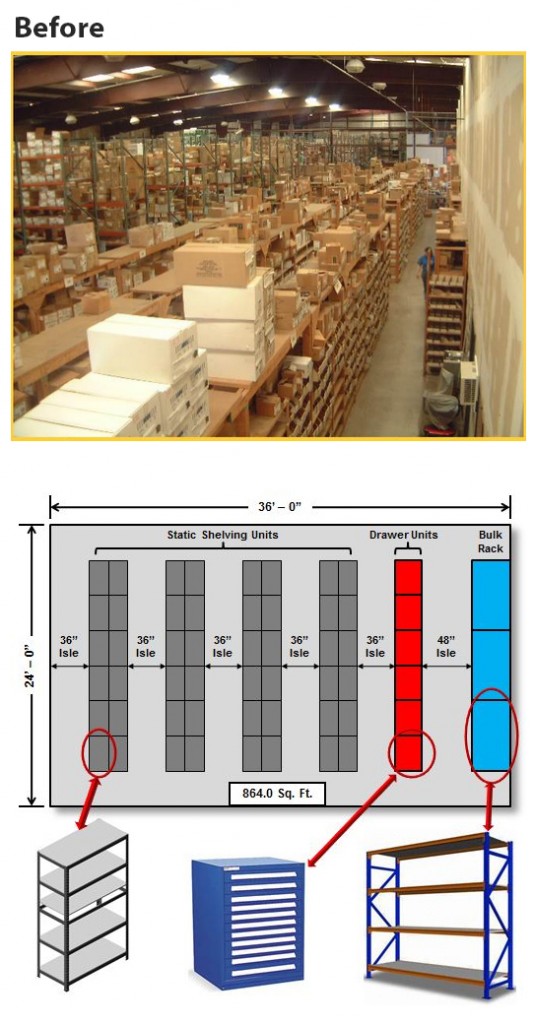

Is this what your warehouse or factory floor looks like?

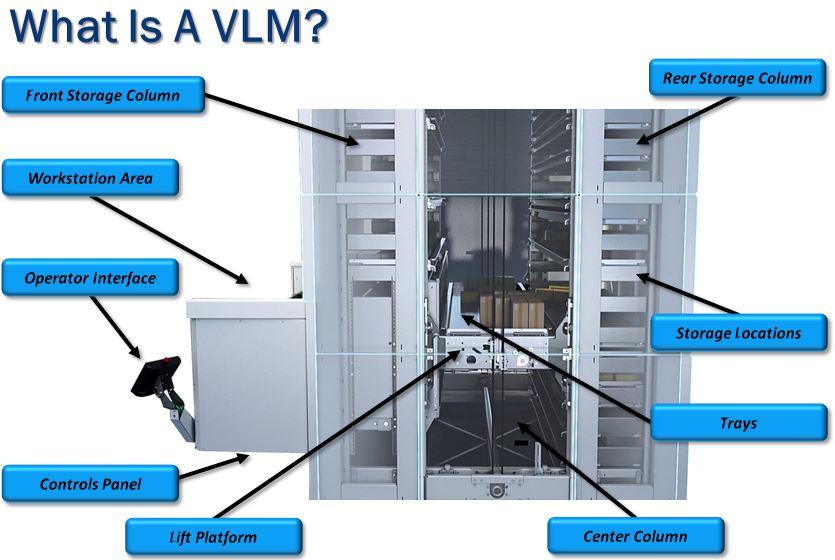

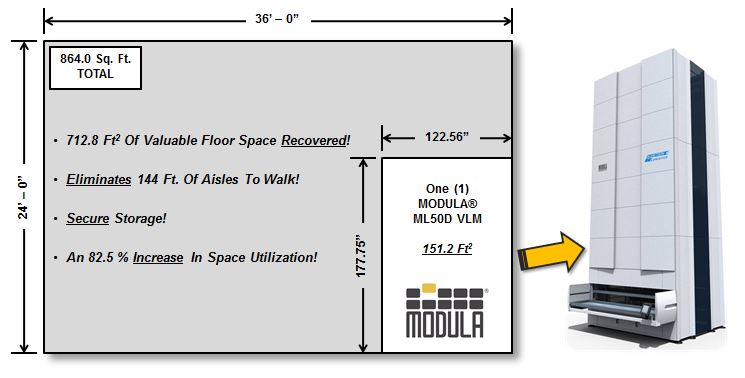

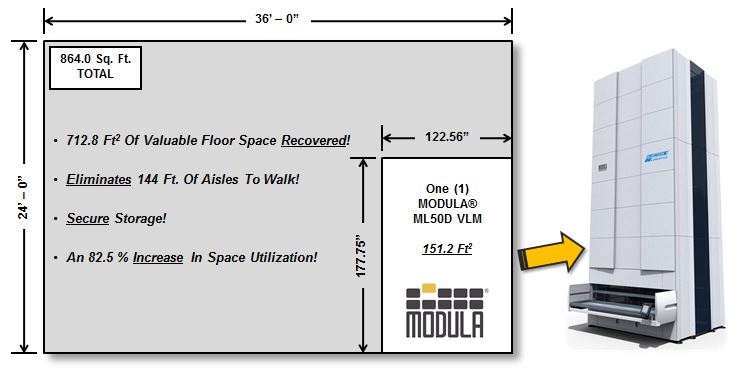

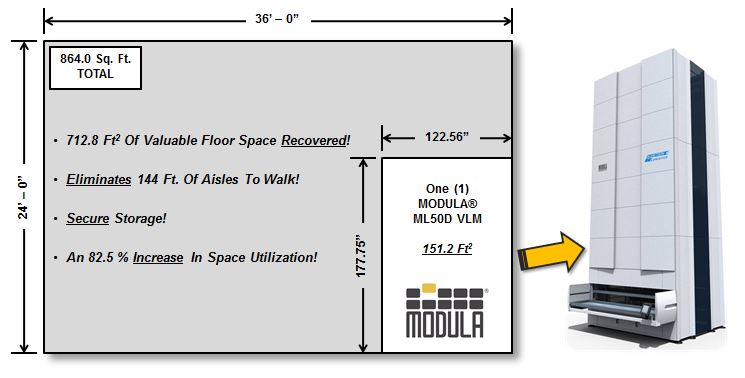

The most common reason for justifying the purchase of a vertical carousel or vertical lift module (VLM) is to free up valuable existing floor space for alternative uses (rather than simply storage), such as manufacturing, processing or shipping.

Well, you certainly can build an addition or otherwise acquire more building space through purchasing or leasing real estate. But then, of course, you’ll have to deal with the tremendous expense, potential location issues, permitting, and possibly second-site management issues. Is that what you really want?

So, what are the alternatives?

If you add a mezzanine and shelving or pallet racking, you’re getting warmer – but that’s often only a partial or temporary solution. It may still be costly, and you’ll likely experience slower pick rates and reduced efficiencies.

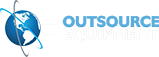

Learn more about the vertical lift module

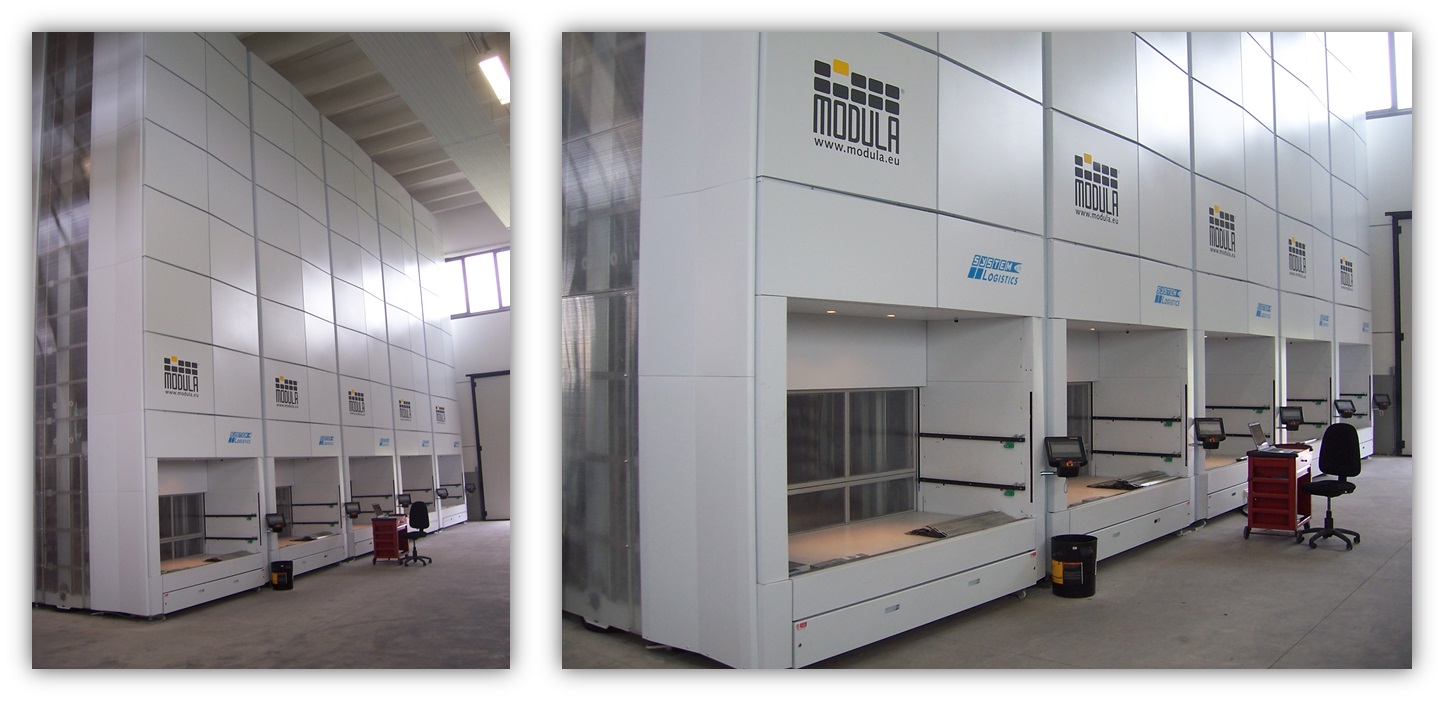

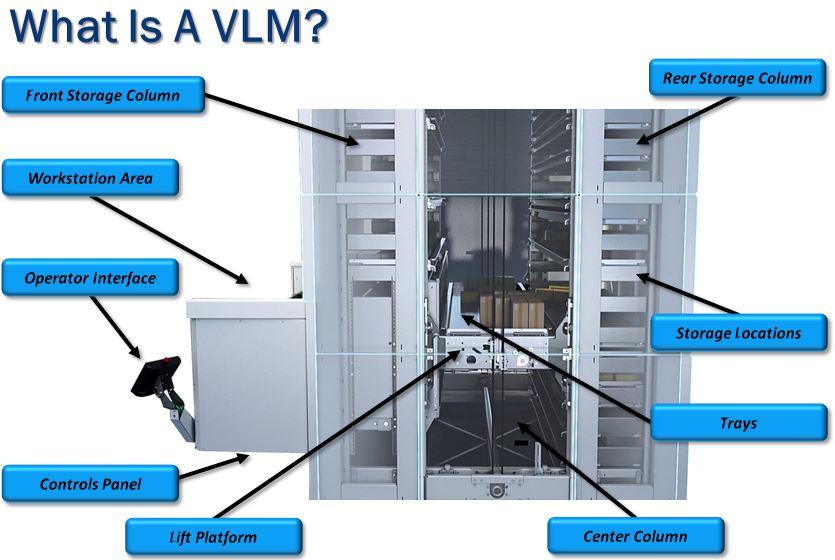

The solution is a vertical lift module!

A vertical lift module or VLM is a space-saving automated storage and retrieval unit with a wealth of benefits (see below).

The Benefits of Using a Vertical Lift Module

Besides significant savings in floorspace, there are some other key benefits of using a vertical lift module.

1. Improve Picking Productivity

1. Improve Picking Productivity

The process of picking parts in a shelving, drawer or rack storage system is inherently slow.

These “Man to Goods” based systems involve walking and often searching for each SKU.

“Man to Goods” systems generally result in 30 to 60 lines per hour, per person.

Automated Storage “Goods to Man” systems can result in rates of 150 to 300 lines per hour per person.

The result is labor savings!

2. Improve Ergonomics and Safety

The process of picking parts from shelving and rack can be physically tiring and sometimes harmful or dangerous for the employee.

“Man To Goods” systems involve walking, climbing stairs and or ladders, bending, reaching, etc.

“Goods To Man” systems eliminate most of these issues.

On the job injuries are very expensive, and can include lost time, medical bills, higher workers compensation rates and lawsuits.

3. Improve Product/Material Security

Most shelving type systems provide little or no security for the parts being stored. The area may be fenced or gated; however, for those with access to the area all parts are available all of the time.

Most automated systems, though, provide a good degree of parts security:

- Password protection with activity reporting

- Random storage locations

- Manual picking is physically impossible

Virtually Limitless Target Industries and Applications

Industries:

- Metal Working and Related

- All Manufacturers

- Parts Distribution

- Heavy Equipment Dealers

- Pharmaceutical Manufacturers

- HVAC Distributors and Dealers

- Aerospace Related Manufacturers

- Food/Beverage Manufacturers and Distributors

- Grocery/Health & Beauty Distributors

- Military Bases and Defense Manufacturers

- Many more…

Applications:

- Parts Storage

- Label Storage

- Tooling Storage

- In-process Inventory

- Dies and Fixtures

- Sheet goods, Rolls, Cylinders

- Garment or Apparel Storage

- Optical Storage

- Maintenance Parts and Tools

- Weapons and Military Depots

- Many more…

Inefficient Warehouses Come in All Shapes and Sizes!

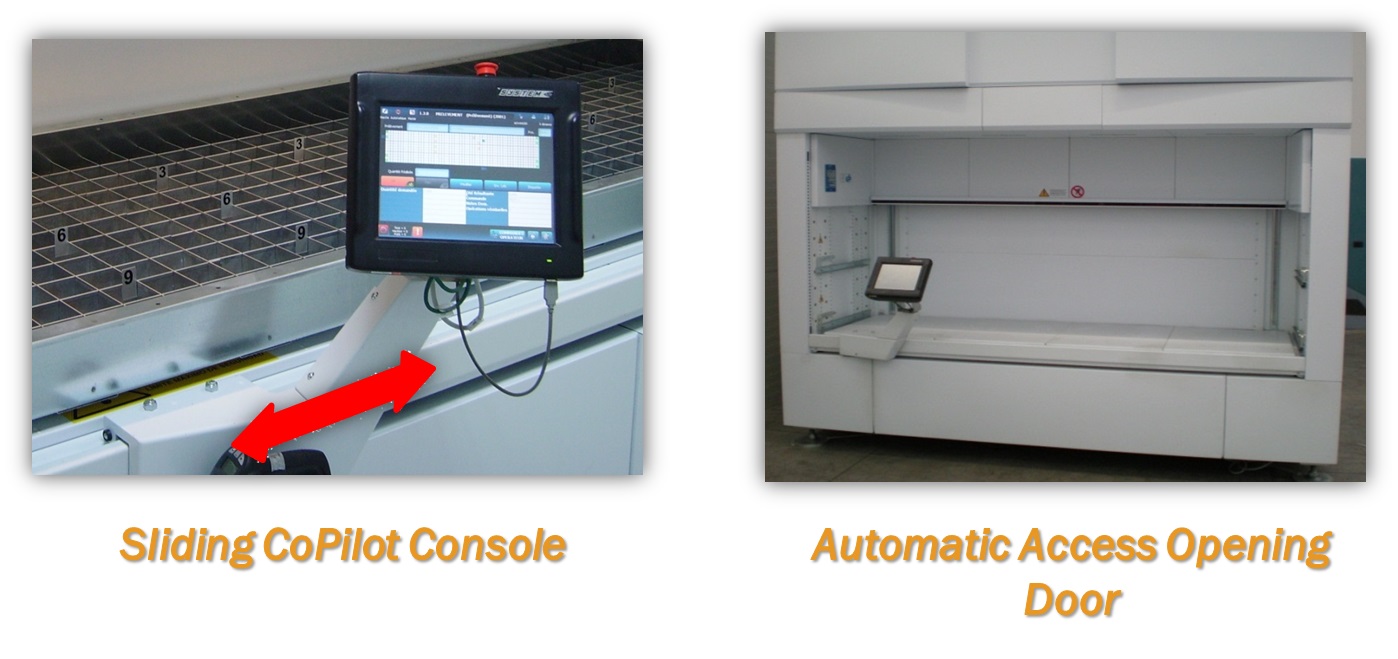

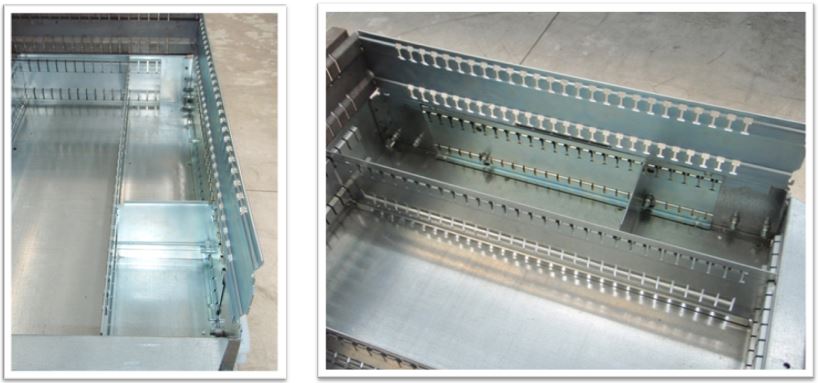

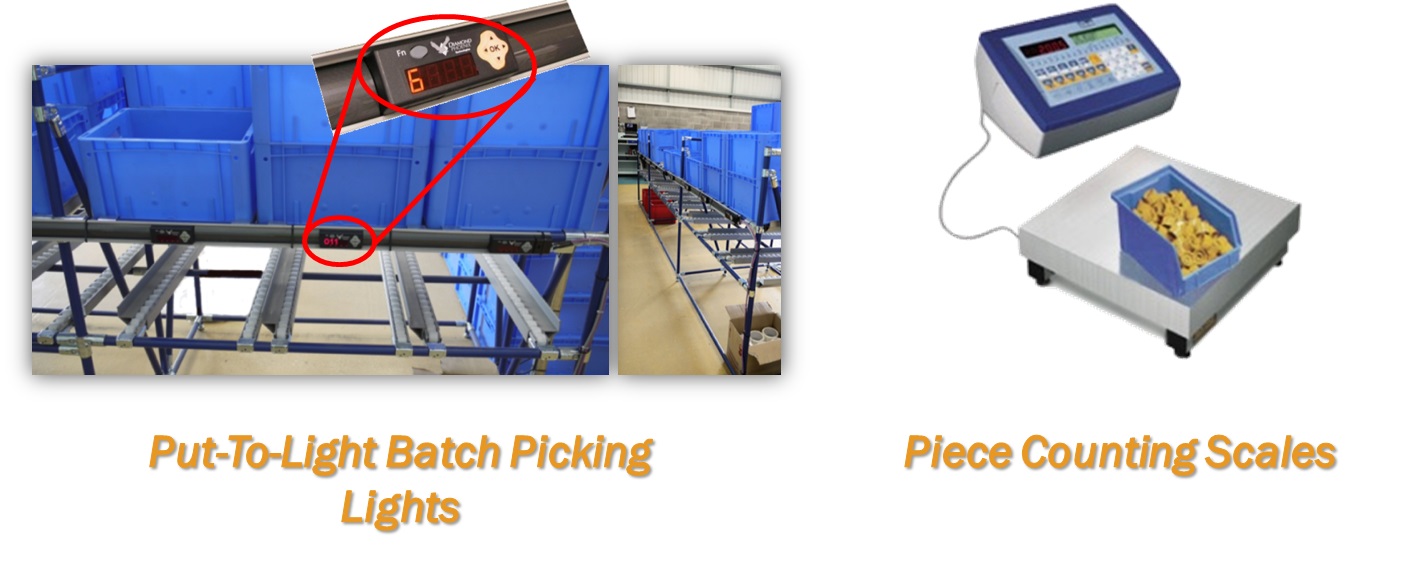

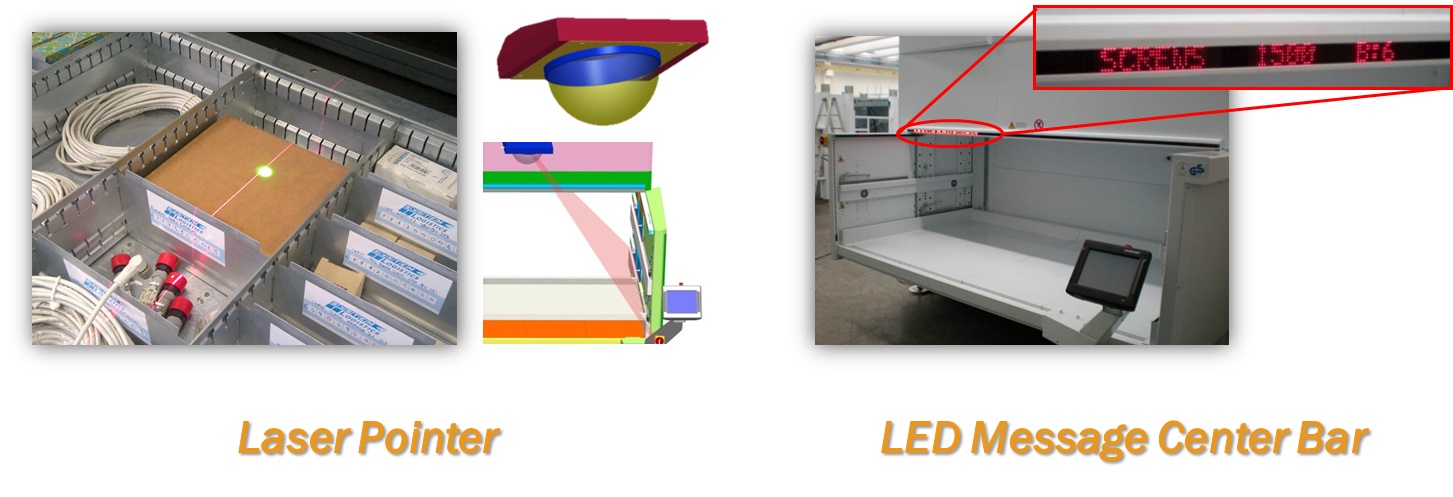

Customization and Specialization

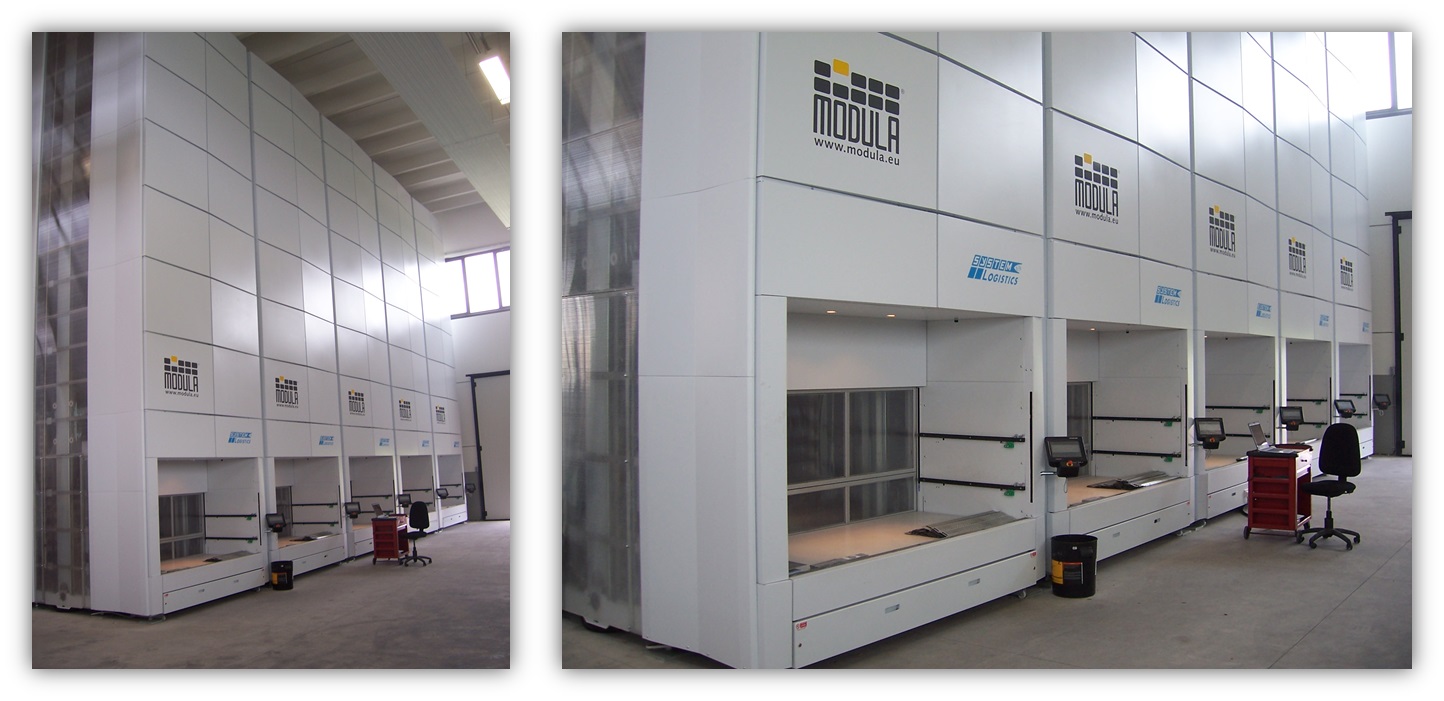

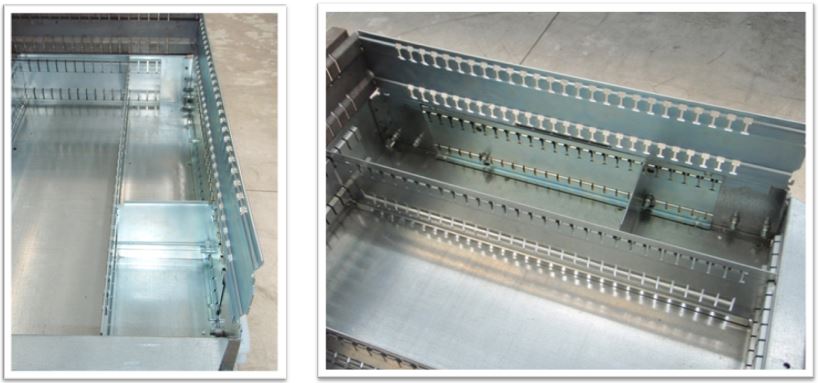

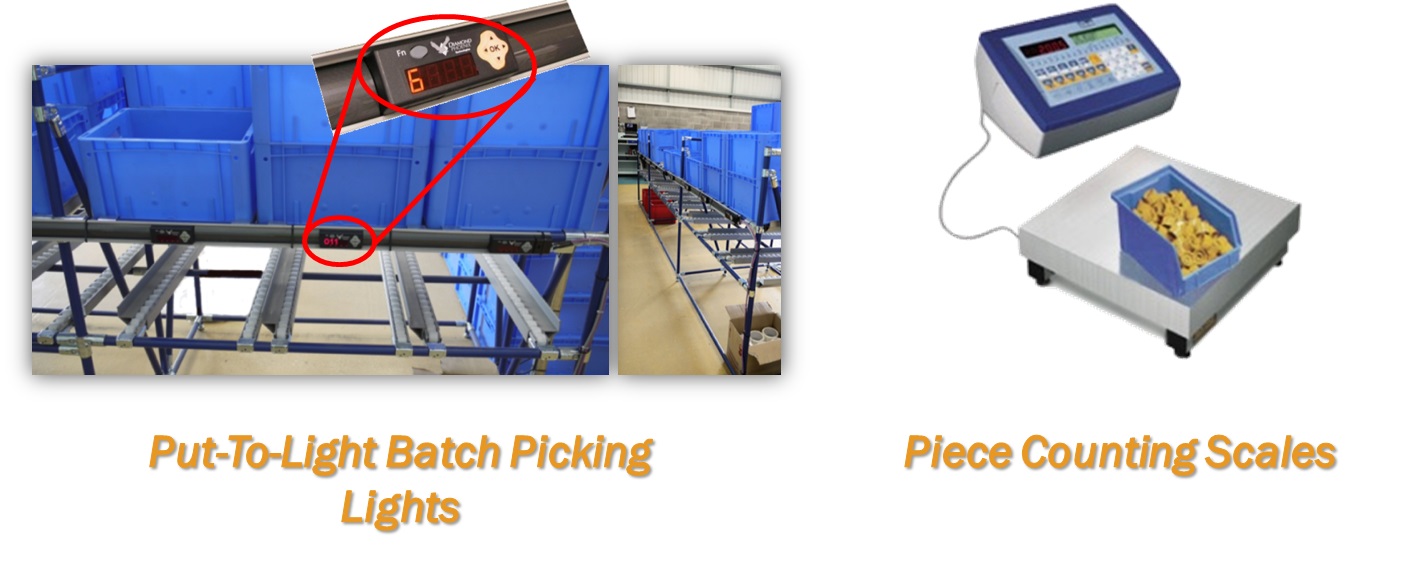

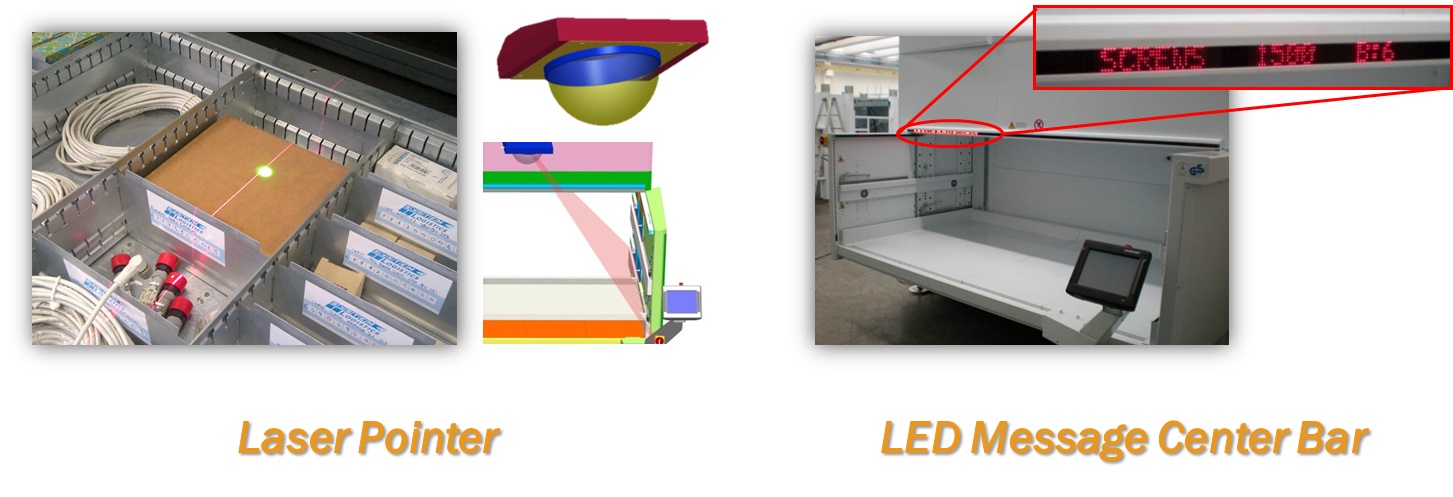

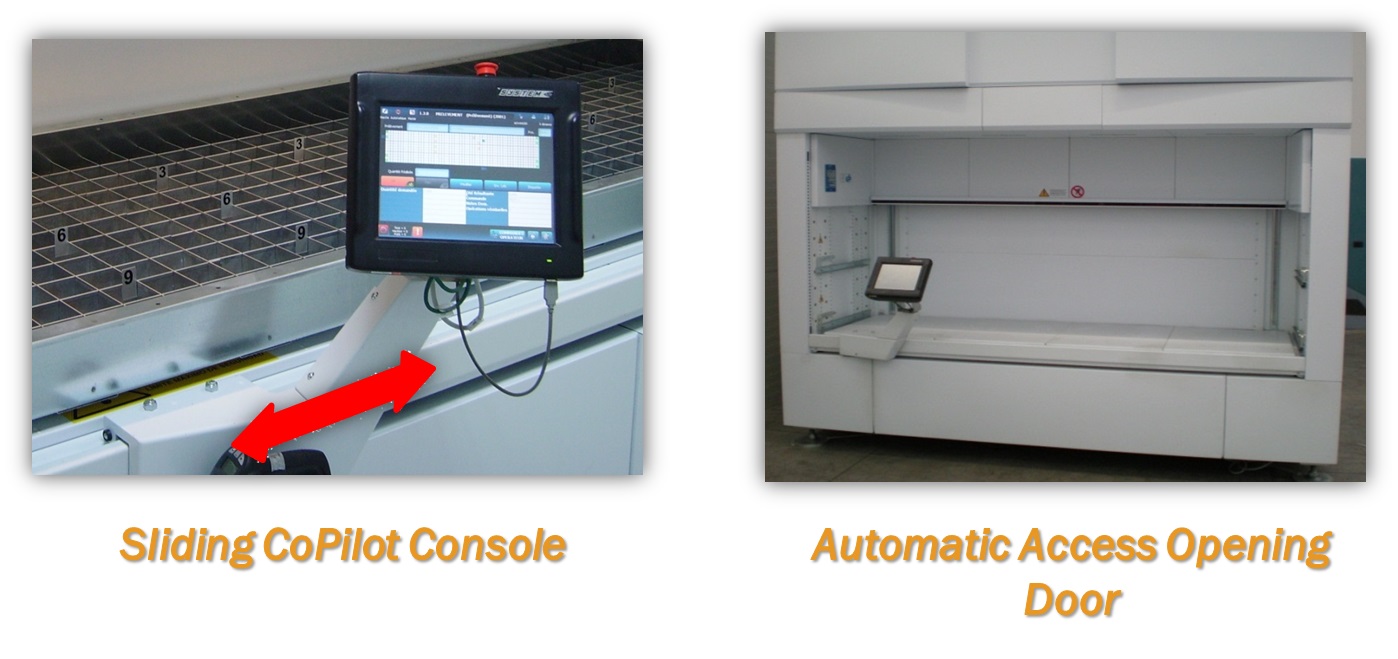

Outsource Equipment is an exclusive dealer for the Modula line, including the Modula Lift. In addition to its many standard-yet-innovative features, the Modula Lift has many optional items and accessories so that you can customize the equipment for your operation:

And All For A Lot Less Than You Might Think!

You can get a brand-new Modula Lift unit from Outsource Equipment for as little as $45,000. Give us a call today and we can help you figure out exactly what material storage systems will work best for you and provide you with the greatest – and quickest – return on investment. We also offer used vertical lift modules and other used warehouse equipment for sale. Check out our inventory or give us a call.